Manufacturing could be a beneficiary of Theresa May’s interest in formulating a cross-government industrial strategy. The new ideas could lead to new investments and projects with a positive impact on manufacturing and other technology-intensive sectors. In constructing and implementing a framework for thinking about industry, Britain needs a new agency: an Office of Industrial Strategy. It would draw up the details of the strategy and monitor their compliance. Through this agency, the government should provide financial support in some areas – such as helping new or existing businesses to develop technologies and improve skills. There must be a link with education and training. Young people keen to learn about engineering should be given the capabilities to develop the skills they and businesses need. Included in this broad thrust should be the promotion of role models –we should talk about successful people and businesses that can attract others to follow the same line. The new strategy could lead to something many would welcome: a re-industrialisation of Britain.

A new initiative

The strategy takes the UK into a new realm of policy – and could be a welcome boost for manufacturing.

Since the 1970s British governments have tended to shy away from anything that could be termed “industrial policy". That is why Theresa May's announcement that the UK will have a "proper industrial strategy to get the whole economy firing" is a significant step. The new prime minister's industrial epiphany is welcome. It marks an apparent willingness to try to understand better the mechanisms by which industrial activities affect areas such as jobs, the environment and social wellbeing. Beyond this the announcement paves the way for government policies that may prove desirable in catalysing and enabling specific industrial activities - in manufacturing as well as other sectors. May’s push for an industrial strategy is likely to take the government further than the moves in this direction during 2010-2015. The then business secretary Vince Cable was responsible for several key initiatives, but with muted support from the rest of the government.

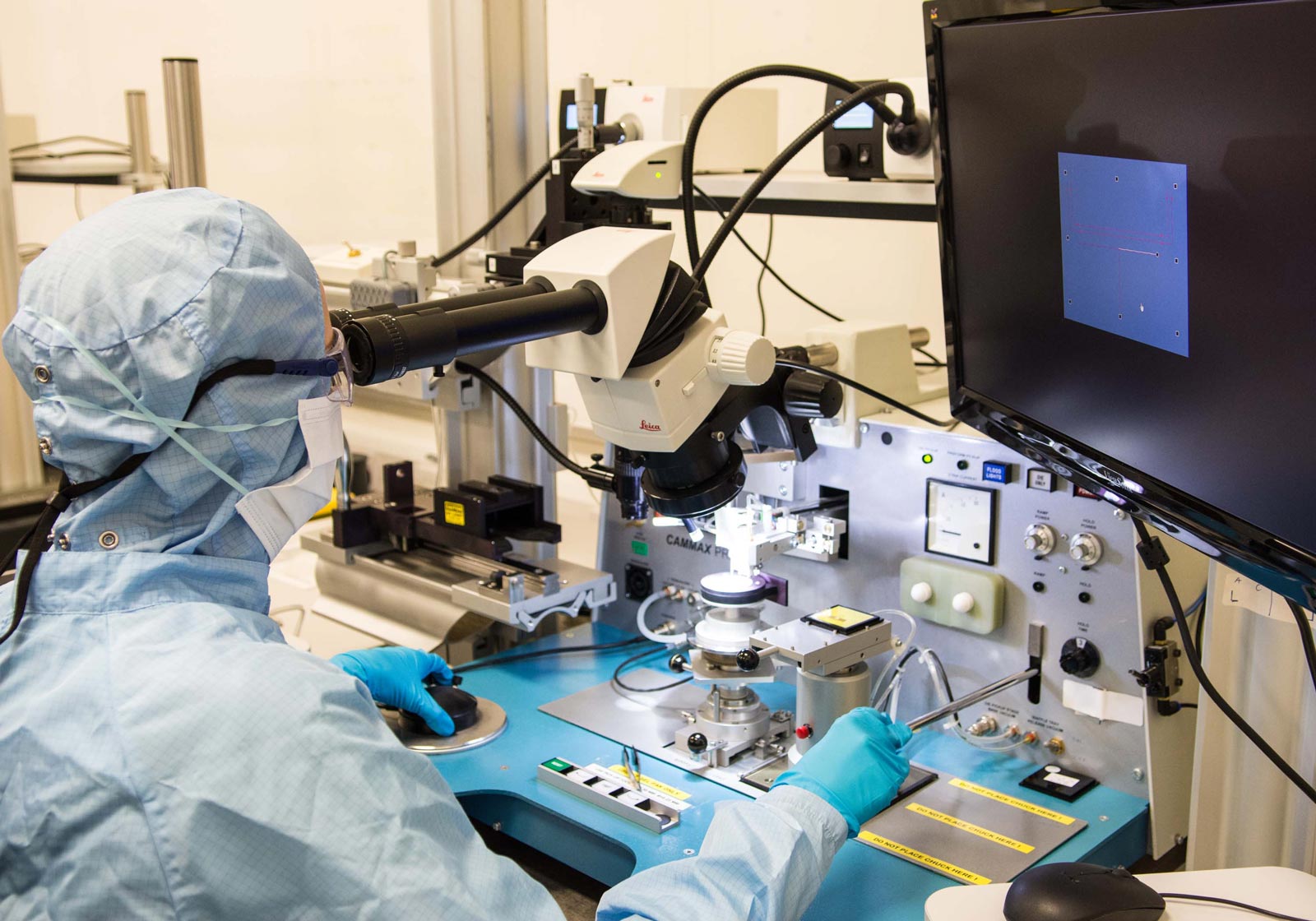

Institute for Advanced Manufacturing and Engineering, Coventry University

Institute for Advanced Manufacturing and Engineering, Coventry University Setting strategy

The new strategy will be assembled by a team of top civil servants. Theresa May seems determined to get her top ministers to line up to back the new approach.

Civil servants are getting down to the task of drawing up a strategy – a number of details of which have already become public. The old Department for Business, Innovation and Skills has had industrial strategy added to its title, while being merged with the Department of Energy and Climate Change. The new entity is called the Department for Business, Energy and Industrial Strategy. May is chairing a new committee of top ministers covering economy and industrial strategy. This signals that, at least in matters dealt with by this group, the new BEIS is being hauled up to the same level as the Treasury – which has overall responsibility for the economy. It also underlines May’s commitment to get all her ministers lined up behind the idea of an industrial strategy, something that failed to happen in the two governments of her immediate predecessor David Cameron.

Ideas framework

The prime minister has announced the main elements of the new thinking. Training, skills and energy will be at the centre of the strategy – but many finer points have still to be settled.

Promoting skills will be at the heart of the new industrial strategy, according to Theresa May. In providing an outline of the new ideas in January 2017, the prime minister set out a determination to make the strategy work, even in the face of the uncertainties triggered by Britain’s decision to quit the European Union. Fears have been raised, for instance, that Brexit could damage the UK’s successful car manufacturing industry – much of which depends on exporting to (and receiving components from) nations in the EU.

In one initiative, ministers will provide £170m to set up “institutes of technology” to provide top-level training in Stem subjects — science, technology, engineering and mathematics. There will also be an expansion of maths education in secondary schools. The government also wants to reinforce “clusters” of specialist industries in small geographical areas by working with education establishments and local “cultural institutions”. Efforts are to be made to reduce power costs for industries judged as strategic.

Among the key “pillars” identified by May as being at the core of the ideas are strong investments in science, research and innovation, ensuring businesses can find the finance and management skills they need to grow, cultivating “world-leading” industrial sectors and boosting economic growth. A discussion paper published by the government says ministers should develop a more strategic approach to inward investment while doing more to identify big potential exporters punching below their weight.

Recent context

Vince Cable pushed on with ideas for industry policy but failed to win complete backing of others in government.

No one is talking about the UK reverting to the heavy-handed industrial planning of the 1970s. Nonetheless May's policy interests will push her administration in a different direction to that of other recent UK governments. But it is also important to consider the efforts of Cable (now Sir Vince Cable) when he was business secretary in the 2010-15 Conservative/Liberal Democrat coalition. Cable – a Liberal Democrat who is now a member of the Made Here Now advisory board - initiated a number of moves that had a positive impact on industry policy. Some of his ideas built on initiatives that emerged from Lord Mandelson, business secretary in the final year of the previous Labour administration. During this time, Mandelson had also come round to thinking the government should play a more interventionist role in industry.

In 2013 Cable set out why organising connections between government and industry was important. “A stronger economy won’t be built overnight. It won’t simply emerge of its own volition. It will come from long-term thinking and the government working in partnership with business…Our industrial strategy is…strengthening manufacturing supply chains, supporting new designs and developing skills.” But Cable’s efforts failed to win support throughout the coalition. Following the Liberal Democrats’ removal from government after the 2015 general election, the idea of an industrial strategy faded away. In Cameron’s brief second stint as prime minister – from the 2015 election until the June 2016 Brexit vote that led to his resignation – government leaders rarely if ever mentioned the term. What happens now?

Buds of May

In constructing a new strategy, there is plenty of room to manoeuvre. We need to understand how manufacturing relates to the rest of the economy.

Speaking before the first meeting of the government's new economy and industrial strategy committee in August 2016, and just under a month after she took over as prime minister, May ventured the sparsest details about her ideas on industrial strategy. She said it would focus on “on improving productivity, rewarding hard-working people with higher wages and creating more opportunities for young people so that, whatever their background, they go as far as their talents will take them”.

Such a vague statement appears to leave plenty of room for new thinking. The job of assembling the strategy is being given to a team of BEIS officials. There will be a particular focus on new industrial opportunities in the UK that an activist policy could stimulate. The likely impact on industry – both potentially positive and negative - of Britain's planned departure from the European Union will be considered.

Manufacturing will be assessed alongside the other main sectors. It now accounts for only about 10 per cent of economic output as this is normally counted. But it plays a disproportionate role in spreading wealth, skills and ideas throughout the economy. Merchandise is the biggest component of world trade. Consequently manufacturing has a big impact on UK trade. If Britain is to narrow its enormous trade deficit – which in 2015 stood at £38.6bn, or 2.1 per cent of GDP – it will almost certainly need to step up manufacturing exports.

Other influences of manufacturing are related to its linkage to the rest of economy through a number of direct and indirect impacts. There is a particular link with services. For instance, many products ranging from jet engines to lifts are often sold with some of their capital cost wrapped into long-term maintenance contracts. Unravelling how much of price paid by the customer is down to manufacturing and how much is connected to service is practically impossible. This underlines how the dividing line between manufacturing and services –particularly in certain companies - is becoming harder to discern. For these reasons manufacturing is likely to feature heavily in the civil servants’ assessment.

Driving change

Britain needs a new agency to implement the new ideas. Some parts of the approach can be modelled on the US.

If Britain does end up with a focused industrial policy in which manufacturing plays a big part, it will be doing no more than joining the ranks of other countries - from Singapore to the US - that put detailed policies towards industry at the heart of their thinking. Britain will need to steward the strategy properly. A new agency is need to do this: an Office of Industrial Strategy.

The office would answer to three government departments - BEIS, the Treasury and the new Department for International Trade. It would both promote the country’s industrial strategy and assess how well it was performing. It would have an important analytical role. The office would assess where Britain stood in the world in key industrial sectors and examine strengths, weaknesses and opportunities, especially in the light of Brexit. It would be especially important to examine Britain’s performance within the context of other major competitors, particularly the rising economies of China and India.

A model for the analytical side of the OIS is the Office of Technology Assessment. This highly effective arm of the US Congress operated from 1972 to 1995. It provided Congress and the rest of government - along with the wider public – detached and detailed studies of how the US was faring on a range of the key technological issues of the late 20th century. Analysing manufacturing would be particularly important.

Growth sectors

Supporting excellence is good. Picking winners need not be bad.

Among other jobs, the new office would determine where Britain excels in manufacturing. These are the areas where government action might be expected to have the biggest impact. The approach would have to be rigorous and even-handed. There would be no need to spend large sums on government handouts. A lot could be done through general promotion, a modest tweaking of policies in fields such as training and R&D support and possible modest tax breaks. Areas in which Britain already has a competitive advantage include industrial biotechnology, low-carbon car engines, high-value food processing, niche areas of clothing, scientific instruments, specialised medical devices and customised electronics. These are the sorts of areas where industrial policies should be focused. While considering the growth fields, we have to be careful about being too restrictive.

Focusing on specific sectors such as aerospace and automotive – no matter how broad and important they are – raises the prospect of ignoring companies that are performing well in parts of the economy normally considered to be less advanced. It makes no sense to consider only those manufacturers in certain fashionable fields as part of the “growth sectors” for manufacturing. Others – perhaps in areas such as food processing, bicycles and metals processing – may also be performing well and deserve their share of attention and support.

The idea of channelling resources to favoured areas of the economy can be controversial. Critics argue that this stance is similar to efforts by governments of the 1970s and before this to “pick winners” – channelling grants and tax breaks to favoured industry sectors, often with poor results. This view is nonsense. Following a strategy of this sort does not have to be disastrous. Prior to the 2016 Rio Olympics, Britain tried to identify its most promising fields of sporting prowess. It fed them with money and resources. The reward was a fine haul of medals. Something similar could work in manufacturing.

Cable’s legacy

We should build on Cable’s approach in 2010-15. A number of his initiatives were welcomed in industry.

Former business secretary Cable encouraged a focus on the way manufacturing - and other sectors - connect with other parts of the economy. There was a particular emphasis on supply chains, the processes by which companies assembling goods in the UK source components and subsystems. Cable’s department was keen to examine ways in which gaps in the UK supply chain could be plugged – for instance by encouraging companies to set up UK plants to make parts for car plants that previously relied for these items on overseas suppliers. The former business secretary also initiated studies of specific industrial sectors to pinpoint those with the most promising competitive positions. There was an effort to devise specific policies – for instance on training, skills or research – that might be helpful to specific parts of the industry economy judged to have good growth possibilities. A particular focus was placed on aerospace and automotive – two areas where the UK’s industrial position remains strong - and a number of useful policies set in train. The government set up a series of Catapult advanced research centres – in fields from new plastics composites to stems cells – to promote industrial development done in conjunction with companies.

According to a 2013 government document, the coalition was committing “over £4bn” to industrial strategy, with the money due to be spent in fields such as building up a new British Business Bank, helping supply chains and support for sectors including aerospace, automotive and agricultural technology. Cable's thinking won praise and support from industry leaders for his willingness to grapple with important issues and set up some important initiatives.

In his time in government, Cable gained some support. George Osborne, Cameron’s right hand man as chancellor, made manufacturing a highlight of his 2011 Budget speech, conjuring up a vision of a Britain “carried aloft by the march of the makers”. But Cameron and Osborne failed to match their occasional bursts of rhetoric with firm actions. After the 2015 election, industrial strategy vanished from the agenda, only suddenly to reappear.

Import substitution

Britain should become serious about reshoring. Dyson could be a focus.

Assuming Brexit happens, Britain will be free from the European Union’s rules over state aid. It would have more leeway to provide funds to businesses investing in projects judged to be socially or economically. This new freedom should be applied with wisdom and imagination to create new manufacturing ventures aimed at import substitution. Part of this should involve a large increase in "re-shoring" of production facilities, in part capitalising on the lower value of sterling and the potential of new technology to catalyse manufacturing projects.

The new OIS would be given a brief to monitor this trend. It would work out how much reshoring was happening and how this fits in with other manufacturing trends including new investments taking place without any relocation of facilities and (less positively) ventures shutting down in the UK because they are uncompetitive or their management is poor. High profile examples of reshoring would be encouraged. Appliance maker Dyson would be a good subject for this. In the early years of its life the company was a big supporter of UK manufacturing. With a big R&D centre near Bath, it remains a major force in UK engineering and technology. But in 2002 the company pulled manufacturing out of the UK into Malaysia and other Asian countries. Could it be coaxed to relocate some production back to the UK?

Trickle-down effects

Supply chains are important – especially for big projects. They can have a major impact on smaller companies working on huge schemes such as power stations.

Work on plugging gaps in supply chains will continue to be important. That can be done first by identifying where there are problem areas. Then private groups can be encouraged to fill the gaps through investments and expansion. One area of work would encourage new UK ventures that by making goods and selling them to UK based customers would help to substitute for imports. This is one way in which research of the supply chain mechanism is needed.

Special attention needs to be paid as to how big and expensive government projects have an impact on the businesses –especially those based in Britain - that are part of supply chains. Take for instance the £6.2bn programme to build two new UK aircraft carriers, the first of which will start sea trials in 2018. The work has been centred on a big yard in Rosyth, near Edinburgh, and involves hundreds of contractors throughout the UK. Also consider the £18bn Hinkley Point C nuclear station, where the work has yet to begin. The station is expected to begin producing power around 2025.

In both cases, UK industry has had or will have large contracts handed out as part of the supply chain process. In these projects, it would be useful to discover instances of contracts for significant products and services going to businesses based outside the UK, due to lack of skills or resources at home. Also it would be highly useful to research the “second-order” effects of such contracts. These concern the way in which businesses that win orders that involve new technologies or processes can find themselves in a position to win new areas of work because they have improved their level of technical capacity. There may be ways in which government departments supported by the OIS could help to fill the holes in the UK parts of the supply chains – and also to catalyse the “technological upgrading” effect on companies that win contracts. By applying these technology ideas, the companies may hope to gain more work, perhaps in different industrial sectors.

Role models and skills

The agenda on skills and training is crucial. Highlighting young people who have made it in engineering and manufacturing is part of this.

The people and companies behind manufacturing success stories need to be highlighted. Their examples can inspire others to follow in their footsteps. In particular we need to identify young people (aged under 30) who are in successful careers in manufacturing and related areas. People of this age group seem more likely to inspire the younger generation than older people. The job can be done through clever public relations and advertising campaigns that are not influenced by special interest groups. There is a role here for such ventures such as Made Here Now. More recognition should be made of the "maker movement "- small-scale manufacturing often involving young people working with new technologies. The maker movement needs and deserves support. Many people in mainstream manufacturing are unaware of its existence. As well highlighting what’s happening at this level of manufacturing, more could be done to connect small “maker spaces” with bigger companies so they can become part of bigger supply chains.

Promotion of skills should be a big part of the industrial/manufacturing agenda. People gain skills for many reasons – so but not all of which are to do with education policy. Developing the right policies to allow the learning of new ideas is crucial. The social framework in which learning can be done is also important. We need to create conditions such that young people want to learn about engineering, science and technology, because such skills are useful, will provide them with decent careers and are also socially acceptable. In this context learning from role models – people who have followed a similar path and have become successful – can be important.

Concern has been expressed about the big drop in the number of young people studying design and technology at the GCSE exam level. Design and technology is often considered a good gateway to an engineering career. The fall in the number of GCSE students affects the number of students going on to study A-level design and technology prior to a course in higher education. Not only are they less well equipped to embark on design based courses but, more importantly, many young people are now unaware of the massive career opportunities available in design, creative and manufacturing industries that open up as a direct consequence of studying design at school. This may have serious consequences for British industry over the next few years. We need to address these points as part of the industrial strategy.

The cross-government context

An industry strategy won’t work if it is confined to one department of government.

One reason why Cable failed to get his ideas embedded in government in 2010-15 was that his industry strategy went no further than the business department. Any industry policies formulated as part of a broad strategy need to be embedded in all the big spending department of the government – including health, transport and defence. These departments have colossal procurement programmes, requiring the purchasing of large amounts of manufactured goods. Decisions over buying should be made to fit in with the objectives of the industrial policy. Such moves would give the strategy much more weight than confining its operation simply to the business department. The incorporation into the new BEIS of responsibility for energy and climate change gives the department more opportunity to make an industrial strategy include energy planning. Part of the strategy would involve the encouragement of low-carbon forms of manufacturing and the adoption and development of new products – for instance novel gas turbines, batteries and solar collectors – that offer potential in power production and use.

Showcasing innovation

Bring research and science into an industrial strategy – and set up demonstration projects.

There is an obvious link between industrial growth sectors and innovation and technology. Support for innovation needs to be a solid part of the industrial strategy. The Catapult centres have got off to a decent start and should be left to continue their work, until at least such time as when their progress can be properly evaluated. Other existing government schemes such as the R&D tax credit programme have had a positive effect on the technology-intensive businesses that the UK should be trying to support. Room should be found in the industrial strategy for at least one big technology demonstration project. It would be financed jointly by the government and private interests.

A good candidate for such a demonstration project is based on the concept of “massively digitised manufacturing”. This is sometimes referred to as being part of Industrie 4.0 or the industrial internet – the so-called internet of things. This concept lead to two broad sets of possibilities. One is based on making products, the other involves their use. The first way of looking at Industrie 4.0 involves factories where almost all the linkages between different parts of the production process – design, sales, production and after-care – are based around massive quantities of data sent largely between machines.

The second way- centred on how products are used - is the one that may lend itself better to a big technology demonstration project. It requires products and parts to have embedded in them (during manufacturing) sensors and microelectronic components. This means they can operate – when in use –in industrial internet networks. Such networks could link thousands if not millions of pieces of equipment as well as small components.

Smartening up

Manufactured products can be embedded with intelligent sensors so they become interactive. The ideas could transform our urban areas.

In a town or city, the “use-based” way of looking at Industrie 4.0 leads to many possibilities. For instance, engineers could create networks of thousands if not millions of sensors monitoring everything from air pollution to pedestrian accidents. Such machine-to-machine linkages could also supervise and control energy use. The sensors in these networks could be placed in public infrastructure – roadside lights or park benches – and also inside private buildings. There would be big possibilities for making urban areas work more efficiently and be safer places to live and work. On the downside, complex machine networks of this sort could also trigger fears about an unhealthy level of surveillance – think of Big Brother - or criminal hacking that could lead to massive disruption and jeopardise safety. Such potential problems would need to be addressed. Nonetheless the emergence of smart cities based around internet of things technologies – machine to machine interactions – would on the whole be positive. A demonstration of how such a smart city could work – perhaps in one small British town or as part of a larger urban area – could be a great showcase project that could emerge from the industrial strategy.

History lesson

Industrial strategies in the UK are not new – some forms were tried in the 1970s, but the consensus is that they failed to work.

Efforts by UK governments to adopt wholesale industrial planning are not new. But to study them properly we need to go back to 1972. In that year then Conservative prime minster Edward Heath published an Industry Act aimed to promote industrial growth by the regional distribution of industry through tax incentives, development grants and, in some circumstances, financial assistance. It involved the creation of a high powered industrial development advisory board, with members involving many of the top industrial executives of the day. But the envisaged initiatives collapsed under the pressure of the stream of 1970s industrial failures as companies such as Ferranti, Alfred Herbert and British Leyland suffered big financial problems and sometimes disappeared altogether.

In 1974 a general election swept Heath from power and replaced him with the Labour administration of Harold Wilson. In 1975 Wilson enacted a comprehensive Industry Act that created ways for the government to influence industrial development in a number of ways. A 1975 Cabinet paper set out plans for an “agreed national strategy towards industry on a long-term basis”. It foresaw the “better coordination of policies affecting industry having regard to their contribution of growth through industrial efficiency”. The areas the strategy would deal with would centre on manufacturing and North Sea oil. The legislation created a system of “planning agreements” between the government and UK companies so as to encourage coordinated action in fields such as training and capital investment. One of the vehicles for action was a new National Enterprise Board to take public ownership of some existing businesses and push them in new directions. The board would also create new companies in what were regarded as promising fields of technology key to Britain’s future. The most notable example of such thinking was the creation in 1978 of Inmos, a new publicly owned UK semiconductor company which was set up as an effort to rival Intel, the then fledgling US microchip maker. Inmos is generally regarded as a failure. While Intel has developed to become one of the world’s most successful manufacturers in any industry, Inmos struggled to meet its commercial targets and was sold to the private sector in 1978. But Inmos had some positive effects. The company was however responsible for a number of important technological advances, and its legacy lives on in the shape of several small and medium sized electronics and chip design businesses clustered in the Bristol area where Inmos had its UK headquarters.

Leaving Inmos aside, the ideas behind the Industry Act have been largely regarded as unsuccessful. The government actions of the day did little to alter what was then a period of decline for much of UK industry. Most of the instruments of state-aided planning were jettisoned by the new government of Margaret Thatcher that took power in 1979. In a speech in 1978 Thatcher made clear her distaste for this approach: “What we need is not a socialist industrial strategy, but a Conservative strategy for profits, a strategy for disengagement, a strategy for letting free enterprise work”. In the years that followed – in the UK at least – the concepts behind industrial strategy became deeply unfashionable.

Manufacturing spillover

The links between manufacturing and the rest of the economy need to be analysed. They are a critical part of a new industrial approach.

Today manufacturing’s place in the economy is far smaller than it was in the mid-1970s – the last time industrial strategy was adopted as a central tool of the UK government. Back then it contributed 30 per cent of UK economic output – today the figure is about 10 per cent. Services – anything from hotels to running railways - are responsible for most of the rest. A considerable part of economic behaviour fits into the “manufacturing dimension” – the swathe of activity affected by manufacturing - but under conventional statistical rules is not counted as part of it.

There are two ways to look at this – first by considering the direct impact of manufacturing, and the second the indirect.

On the direct side, manufacturing creates jobs, often well paid, that are likely to be spread fairly evenly within communities and the country as a whole. The products and services from manufacturing are relatively easy to trade overseas, creating the opportunity for vital foreign earnings. Energy also enters the picture. Most manufacturing processes use significant amounts of energy. That’s also true for the things – from car engines to power turbines - that manufacturing makes possible. So the products of manufacturing have a big potential to alter the way energy is consumed, opening up possibilities for cutting back on energy is generally and with this carbon emissions regarded as being responsible for solar warming and potential environmental hazards.

Then there are the indirect – or spillover effects. These describe the way manufacturing connects with other parts of the economy. Companies that design products in the UK and own the intellectual property behind them - but choose to have them made elsewhere – would normally be classified as service businesses. However they are in reality as much part of manufacturing as a company that both designs and makes goods in Britain. The same goes for design companies in the UK that work on products later made by other firms either in Britain or abroad.

In another example of spillover, successful production companies stimulate skills and new ideas that can be used to good effect in other sectors, which are often in services. Think for instance of car plant welders who with a small amount of training can work for a company doing maintenance on oil rigs, part of the service economy. In a similar way, if a British manufacturer invents, say, a new form of low-weight cladding material for adding to the exterior of buildings, it might have a specific relationship with a UK firm of architects – which then could win more work as a result of the manufacturer’s breakthrough.

Underlining these points, and sometimes making it difficult to work out the dividing line between manufacturing and services, is that many manufacturers offer services as well as products, using many of the same skills in both parts of the business. That again underlines how the ideas used in manufacturing can migrate elsewhere, helping to create wealth and jobs. Policies for industry need to be framed with this in mind.

Welding of industrial filters at Croft Filters Ltd, Warrington. Photos by Rob Watkins, Winner of the Amateur Photographer Category in EEF's 2016 Manufacturing Photography Competition.

Welding of industrial filters at Croft Filters Ltd, Warrington. Photos by Rob Watkins, Winner of the Amateur Photographer Category in EEF's 2016 Manufacturing Photography Competition.