William Cook wins prestigious industry award

William Cook Cast Products has been honoured with a prestigious industry award celebrating the best of British casting.

The Sheffield-based engineer won the flagship Component of the Year accolade at the annual Cast Metals Industry Awards.

The Cast Metals Federation said William Cook’s valve cage for a US-based supplier to the oil and gas sector combines design and manufacturing innovations, represents “an important step forward for the industry” and opens up new markets for castings.

The product showcases the ingenuity of William Cook’s technical team and the world-class capabilities of the company’s new casting facilities.

The family-owned business has invested millions in a new facility in Sheffield, which combines the latest 3D printing and investment casting technology to allow the rapid manufacture of complex components of unprecedented size and accuracy.

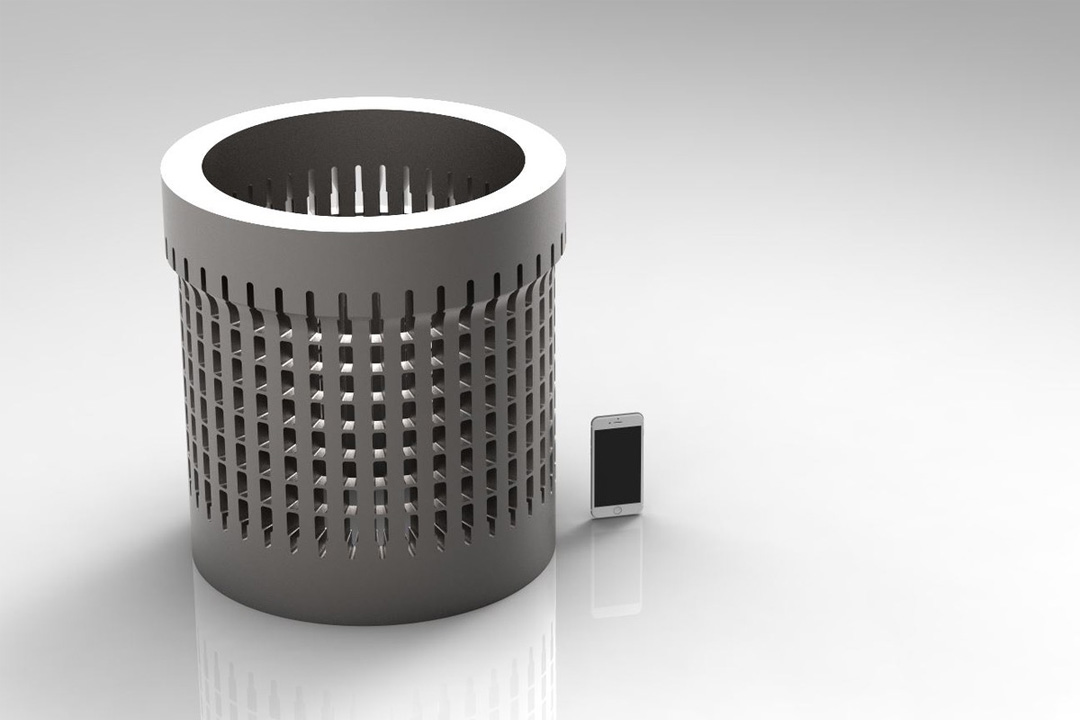

The winning valve cage is used to modify fluid flow in control valve systems, reducing noise levels and improving efficiency. It must withstand corrosion in an aggressive chemical environment.

William Cook engineers combined computer simulation, 3D printing and investment casting technology to make the 70kg valve cage, which had previously been made using a time-consuming and expensive machining process.

Simon Alexander, managing director at William Cook Cast Products, said: “It is a casting that we are very proud of and this innovative casting process saves the customer time and money.

“Traditionally, people have had to design for manufacture, which means they have had to make compromises. Now thanks to 3D printing we have design for function. People can design with freedom. The art of the possible has changed.

“It is a credit to the whole team here at William Cook. To receive the Component of the Year accolade is great recognition for the company, our staff and our customers.”

Pam Murrell, chief executive of the Cast Metals Federation, said: “Through the Cast Metals Industry Awards we can recognise the many remarkable developments that are happening throughout our industry.

“In the UK foundry industry we see examples of innovation, problem solving, risk taking, investment and ambition for the future day in and day out. It is important to give credit to those who lead the way and William Cook Cast Products certainly exemplifies that mindset.”

The awards ceremony took place at the Manor Hotel in Meriden and was hosted by former BBC business personality Declan Curry.

FACTFILE:

William Cook Cast Products is part of William Cook Holdings Ltd, the UK’s largest steel casting group. It is led by chairman Sir Andrew Cook CBE.

The family-owned business manufactures sophisticated components, assemblies and systems for a wide range of applications and has substantial research, development and design resources at its facilities in Sheffield, Leeds and Stanhope.

William Cook’s clients include global energy, transport and defence groups.