GKN showcases low carbon capabilities

GKN has strong technology positions to help our customers meet the needs of their consumers. We aim to deliver the best technology today and develop innovative technologies for the future, maintaining our leadership. Global trends, such as emissions legislation and the drive for green and efficient vehicles, are at the heart of our technology investment.

In 2016, GKN Driveline exhibited at the Low Carbon Vehicle (LCV) event in UK, which takes place at Millbrook Proving Ground. The two-day event highlights the latest trends and technologies in the field of low carbon vehicles, with a distinct focus on electrified vehicles.

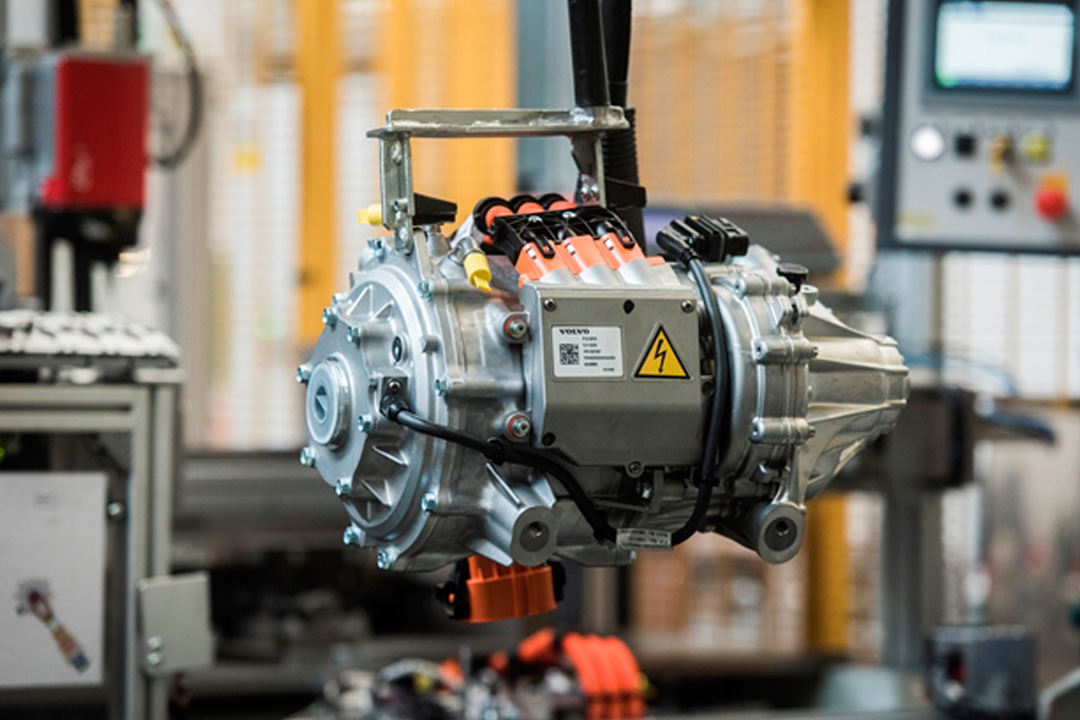

GKN showcased a number of technologies at LCV, including the VL3 constant velocity joint, the co-axial eAxle on the Volvo XC90, the Gen II eAxle on the BMW 2 Series Active Tourer, the Twinster on the Range Rover Evoque and the eTwinster. A carbon fibre propshaft was also on display, which attracted a lot of attention.

GKN Driveline has been advancing the development of electrified vehicles since 2002 and more than 300,000 cars on the road contain GKN eDrive technologies today. Our technology are helping to propel some of the world’s most exciting electric and hybrid vehicles, including the electric axle (eAxle) launched on the Volvo XC90 T8 Twin Engine, the world’s first hybrid premium SUV.

The system debuting on the Volvo XC90 delivers new levels of torque in a significantly smaller package, saving space and making integration into global vehicle platforms simpler, while also enhancing driveability.

The eAxle on the recently launched BMW Active Tourer 225xe is designed for integration into C-segment vehicles, as well as systems that feature on iconic vehicles such as the BMW i8 and Porsche 918 Spyder.