Above: Tokamak Energy’s David Kingham (in yellow jacket) says his company offers big opportunities for young people enthused about new technology. Kingham is pictured with students on work placements: left to right, Opri Martin, Brendan Devlin-Hill, Dan Cross, Fraser Shields.

The technology behind the most potent weapon systems ever devised could help the world move to low-carbon energy production, say the scientists and engineers behind one of the UK’s most innovative businesses.

Tokamak Energy is developing small fusion reactors for producing energy, crucially without the use of fossil fuels implicated in climate change. The science and technology challenges are among the most difficult faced by product developers in any industry.

Meanwhile the UK government has delivered a boost to fusion developments by announcing two big projects, including committing £220m to the design of a fusion power station – the Spherical Tokamak for Energy Production– that could be ready by around 2040.

Indicating confidence that the momentum behind fusion power is accelerating, Tokamak Energy has set out plans to triple employment to 200 by 2022. “We will need more experienced engineers and scientists,” says David Kingham, Tokamak Energy’s executive vice-chairman. "But we will also be offering opportunities to younger technically qualified people who want to get involved in a new industry working at the frontier of new engineering applications.”

The company exemplifies the career possibilities for young people in UK manufacturing and engineering – an area that Made Here Now was established to focus on.

Tokamak Energy also illustrates ways in which manufacturers and technology developers can contribute to reducing carbon emissions. The manufacturing dimension to combating climate change – by finding alternative ways to make products or generate and transfer energy – will feature in stories in Made Here Now in coming months.

The technology being developed in all fusion programmes is based on the ideas behind hydrogen bombs. Detonated in tests but never used in warfare, these weapons are reckoned to be at least 1,000 times more powerful than the atomic bombs that devastated two Japanese cities at the end of the second world war.

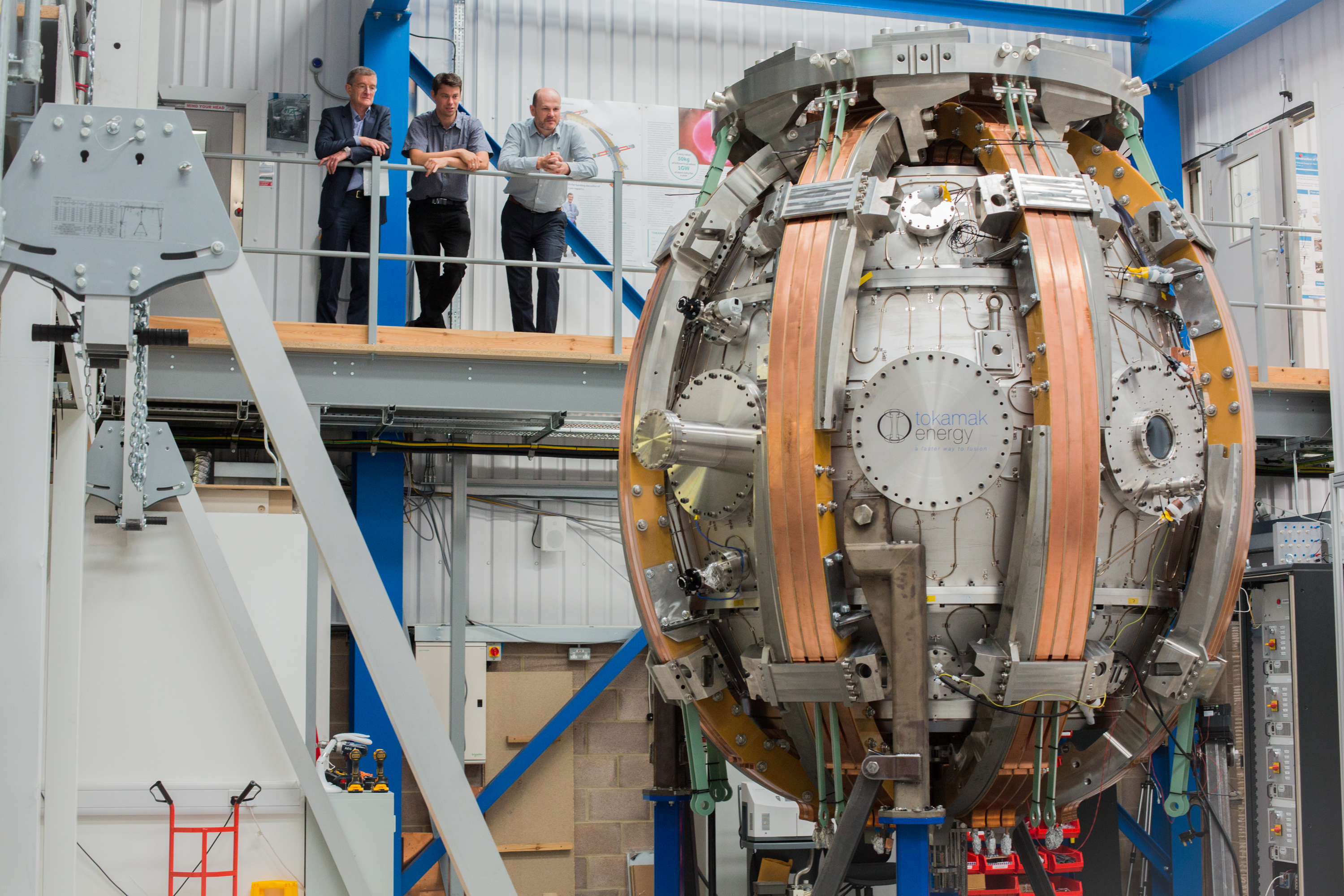

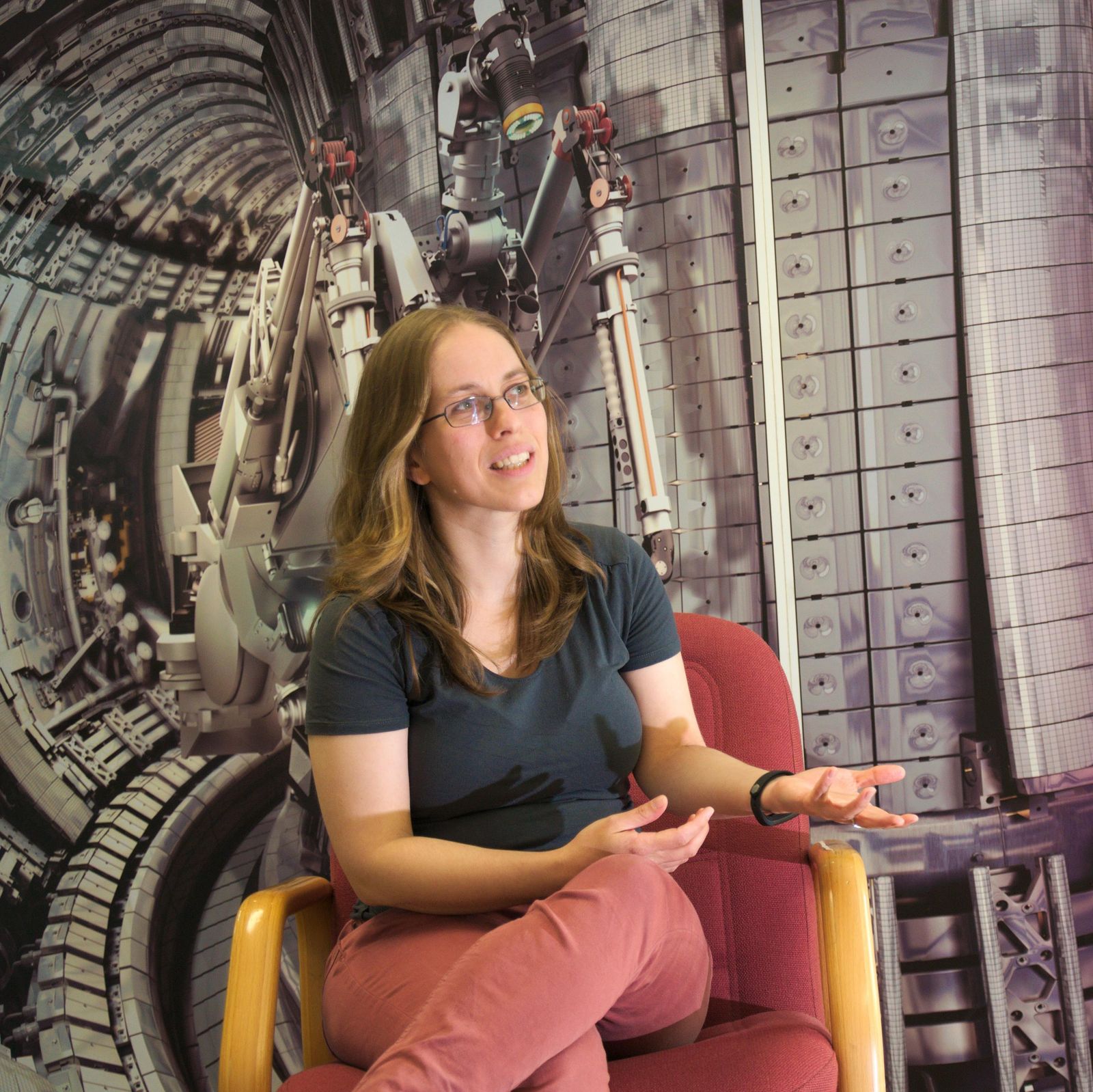

Tokamak Energy’s Melanie Windridge inspects a prototype of the company’s fusion reactors

Fusion is also the process that powers the Sun and other faraway stars. Ultimately it is responsible for human evolution and for all the energy consumed on Earth.

Tokamak Energy thinks its “compact spherical tokamaks” – each the size of a large room – will be ready for full operation by the 2030s. They would be probably be manufactured in several locations spread globally and sell for close to £1bn.

Mark White of UK Innovation & Science Seed Fund, a venture capital company that has invested in Tokamak Energy, says: “I know there will be setbacks but I genuinely think that if anyone can do it [produce working fusion rectors by the 2030s] then they can.”

Based near Oxford, Tokamak Energy employs 65 people and is backed by £50m in investments. It aims to build on knowledge created from some of the world’s big publicly funded programmes in fusion power – such as the Joint European Tokamak in the UK, the International Thermonuclear Experimental Reactor (Iter) in France and Princeton Plasma Physics Laboratory in the US.

Tokamak Energy and its commercial rivals in other countries believe that their approach – based on much smaller reactors than most of those under development in the state sector and using key technical advances especially in magnet technology – could be the way to deliver fusion power relatively soon.

Other companies developing compact tokamaks include Commonwealth Fusion Systems and TAE Technologies in the US and General Fusion in Canada. Two small UK start-ups are Pulsar Fusion and First Light Fusion.

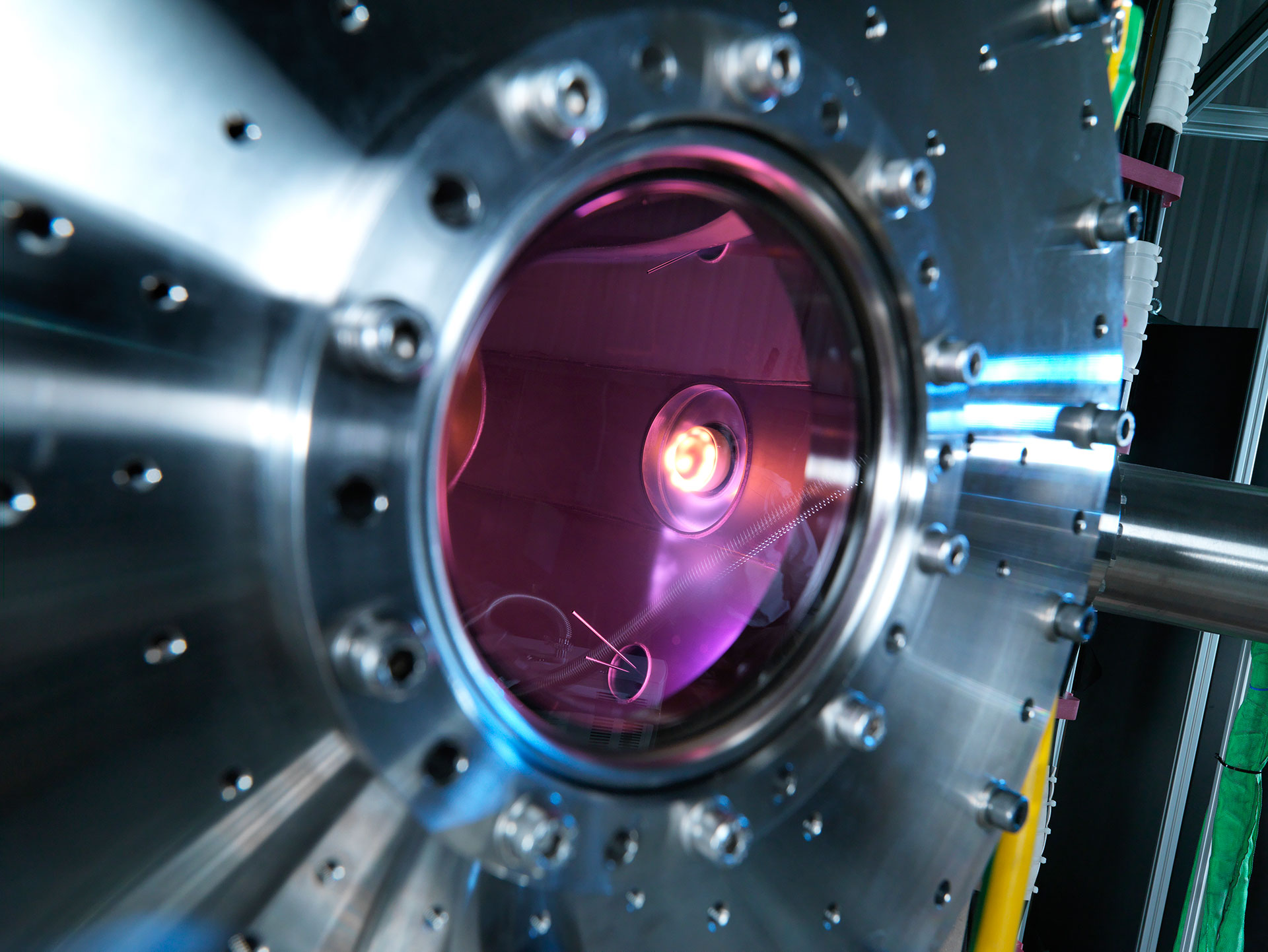

A close-up of part of the complex structure needed to hold in place plasma at a temperature of 150m deg C.

A close-up of part of the complex structure needed to hold in place plasma at a temperature of 150m deg C.

Kingham says: “While the publicly funded research programmes are important in creating much of the scientific asis for what we do, private initiatives are needed to ensure that we move ahead [in fusion] quickly. The extent of climate change means we don’t have the luxury to wait [for fusion power] - we will need it a lot sooner.”

Fusion power is based on forcing atoms such as hydrogen, held as a hot plasma, to combine, which releases large amounts of energy. The technologies Tokamak Energy is tackling include building the powerful superconducting magnets used to contain the plasma.

The plasma will be held at 150m deg C, 10 times hotter than the core of the sun, and will consist of two isotopes of hydrogen, deuterium and tritium. While deuterium is easy to isolate from seawater, making large quantities of tritium is trickier.

It is done by bombarding lithium metal with neutrons using devices called “lithium blankets”, which would be embedded on the walls of working reactors. The process is “possible but difficult”, Kingham says.

An operating tokamak will require 20m amps – an amount of current some 100,000 times higher than that drawn by a typical UK household – operating continuously at a very low voltage. Attaining these high currents requires complex electrical engineering.

“We have a room full of 30 racks of high-tech supercapacitors required to discharge such large amounts of electricity in a short spurt,” Kingham says. So far, the company has cranked up its equipment to deliver 3m amps in short spurts.

The work required is expensive. Tokamak Energy’s research and development spending was £9m in 2017. It rose to £15m the year after and in 2019 it is likely to be almost £20m.

Over the next few years Tokamak Energy will need additional investment of “several hundred millions”, says Kingham. “We don’t anticipate too many problems in raising the necessary money. We have been making good progress and we have had a lot of interest.”

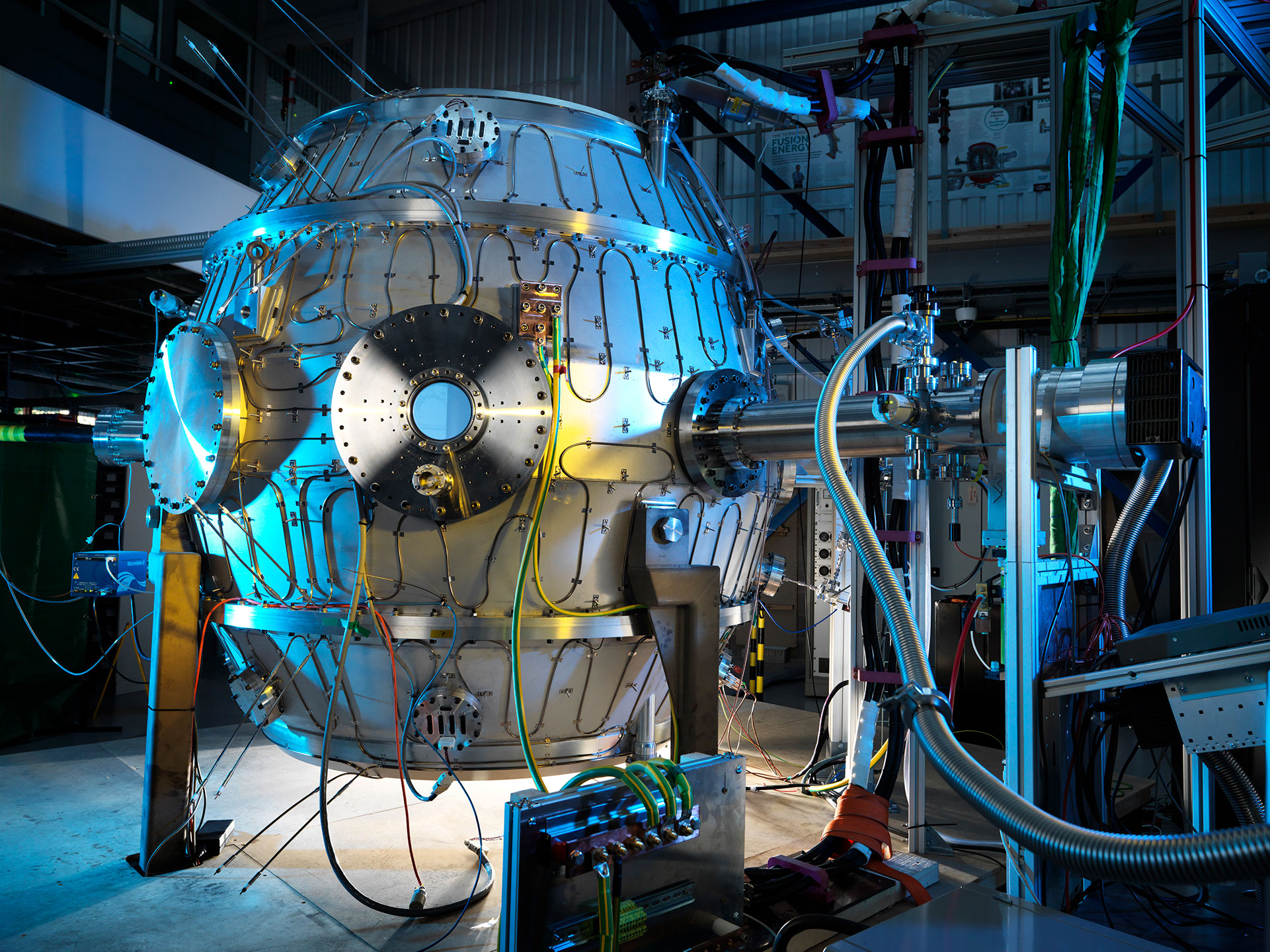

The current prototype system at Tokamak Energy is the ST40, a four-metre-tall steel vessel filled with a hot plasma of hydrogen contained in a powerful magnetic field. The plasma temperature reached 15m deg C in 2018. The company plans to attain 100m deg in 2020.

The next engineering model will be the ST-F1, which Tokamak Energy hopes to build in 2025. At about 10m tall and 10m in diameter, ST-F1 will be considerably bigger than the current machine – and only slightly smaller than what the company hopes will be the working machines.

Assuming the plans work out the final versions of the reactors that Tokamak Energy will build will produce roughly 150MW of electricity, about the tenth of the output of a conventional large gas-fired power station.

Exacting technologies hold the key to making fusion power work

Viewing the future: engineers at Tokamak

Energy are wrestling with some of the world’s most complex technologies

Viewing the future: engineers at Tokamak

Energy are wrestling with some of the world’s most complex technologies

Every second deep inside the sun hundreds of millions of tonnes of hydrogen combine to make energy, some of which reaches Earth and sustain lives. It all sounds so simple – doing the same thing in machines made by humans is a lot harder.

If the ideas being worked on by Tokamak Energy can be made to work, then success in developing several key technologies will a key factor. Among the areas under development at the company are superconducting magnets, digital power control, computerised modelling and 3D printing – which will be used to make key components in working fusion systems in later stages of the company’s developments.

John Bromley of Legal & General Capital, an investment arm of the big financial group and a Tokamak Energy investor, believes the company is ahead of others in the same field “in terms of its technological knowhow” and is also moving ahead in developing the supply chains that would be needed for manufacturing.

Prof David Ruzic, director of the Center for Plasma Material Interactions at the University of Illinois at Urbana-Champaign, has studied Tokamak Energy’s technology programmes and has a research contract with the company. He says that in combining several different technologies, Tokomak Energy has found the “best approach” to making fusion power work.

Fusion involves pushing together atoms that have an immense internal resistance to combining. As a result formidable amounts of energy are needed to start the procedure. It’s the opposite process to fission – the technology for splitting atoms that formed the basis for the atomic bombs the US dropped on Hiroshima and Nagasaki in 1945, causing more than 200,000 deaths.

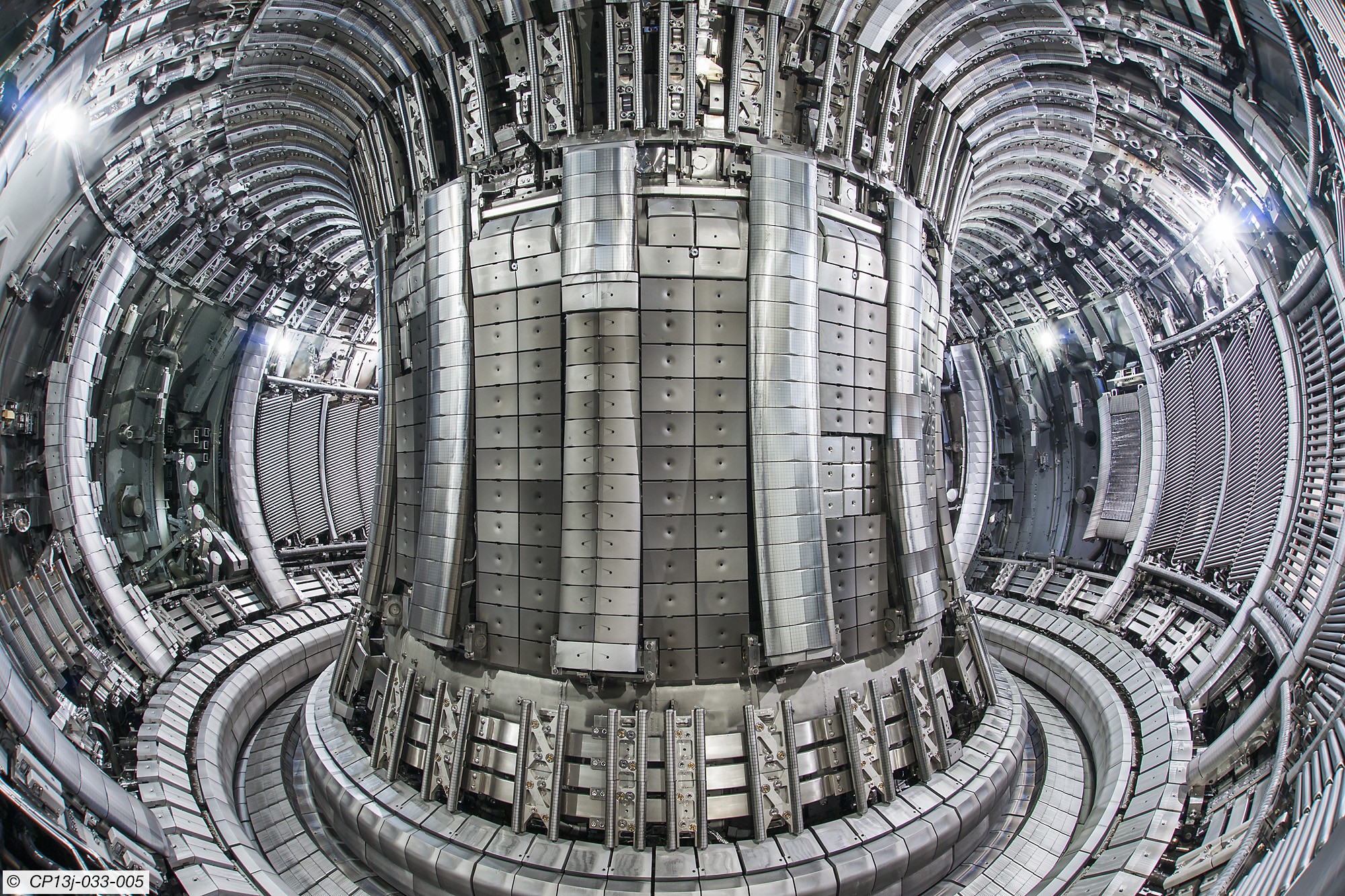

The company’s technical staff liaise with counterparts working on other fusion reactors. Pictured here is part of the interior of the government-funded Joint European Torus fusion reactor, under development in Oxfordshire

The company’s technical staff liaise with counterparts working on other fusion reactors. Pictured here is part of the interior of the government-funded Joint European Torus fusion reactor, under development in Oxfordshire

Nuclear fission – still hard to make work but easier than fusion – is the technology used in conventional nuclear reactors to produce energy.

Probably the most important technology in Tokamak Energy’s fusion power development concerns superconducting magnets. Fusion reactors required incredibly hot plasma, which is extremely diffuse and fragile – a million times less dense than air.

To keep the plasma from being contaminated and cooled by contact with material surfaces, it must be confined in a powerful magnetic field.

Creating the strong magnetic fields that are required is no easy matter. The answer, according to Tokamak Energy – and some of its competitors – lies in “high-temperature” superconducting magnets. Such magnets can provide the high currents needed for ultra-strong magnetic fields and require less energy than more conventional “low-temperature” superconducting magnets.

The difference between high and low temperature – in this context – is critical. A superconductor is a material with zero electrical resistance when it is extremely cold, so it doesn’t heat up when current flows through.

Conventional superconductors are cooled by liquid helium to minus 269 deg C (4 deg K). These forms of superconductors are used in ordinary superconducting magnets – hence the term low-temperature magnets.

High-temperature superconducting magnets are based on materials that become superconducting at around the boiling point of liquid nitrogen, minus 196 deg C (77 deg K). While still cold, this is appreciably warmer than for the magnets’ low-temperature counterparts.

High-temperature superconducting magnets can generate a magnetic field of up to 40 Tesla, 20 times stronger than the MRI (magnetic resonance imaging) systems in hospital scanners.

For its reactors, Tokamak Energy is working on high-temperature superconducting magnets that will deliver 20-25 Tesla.

A key factor has been the availability of skills in the Abingdon/Oxford area around where Tokamak Energy is based. “The fact that this area is one of the world’s leading clusters for superconducting magnets has been hugely helpful,” says David Kingham, executive-vice chairman at the company.

Participants in the cluster include publicly funded research operations such as Oxford University Materials Department and Rutherford Appleton Laboratory as well as companies such as Oxford Instruments and Siemens Magnet Technology. The Joint European Torus international fusion project is also located close by.

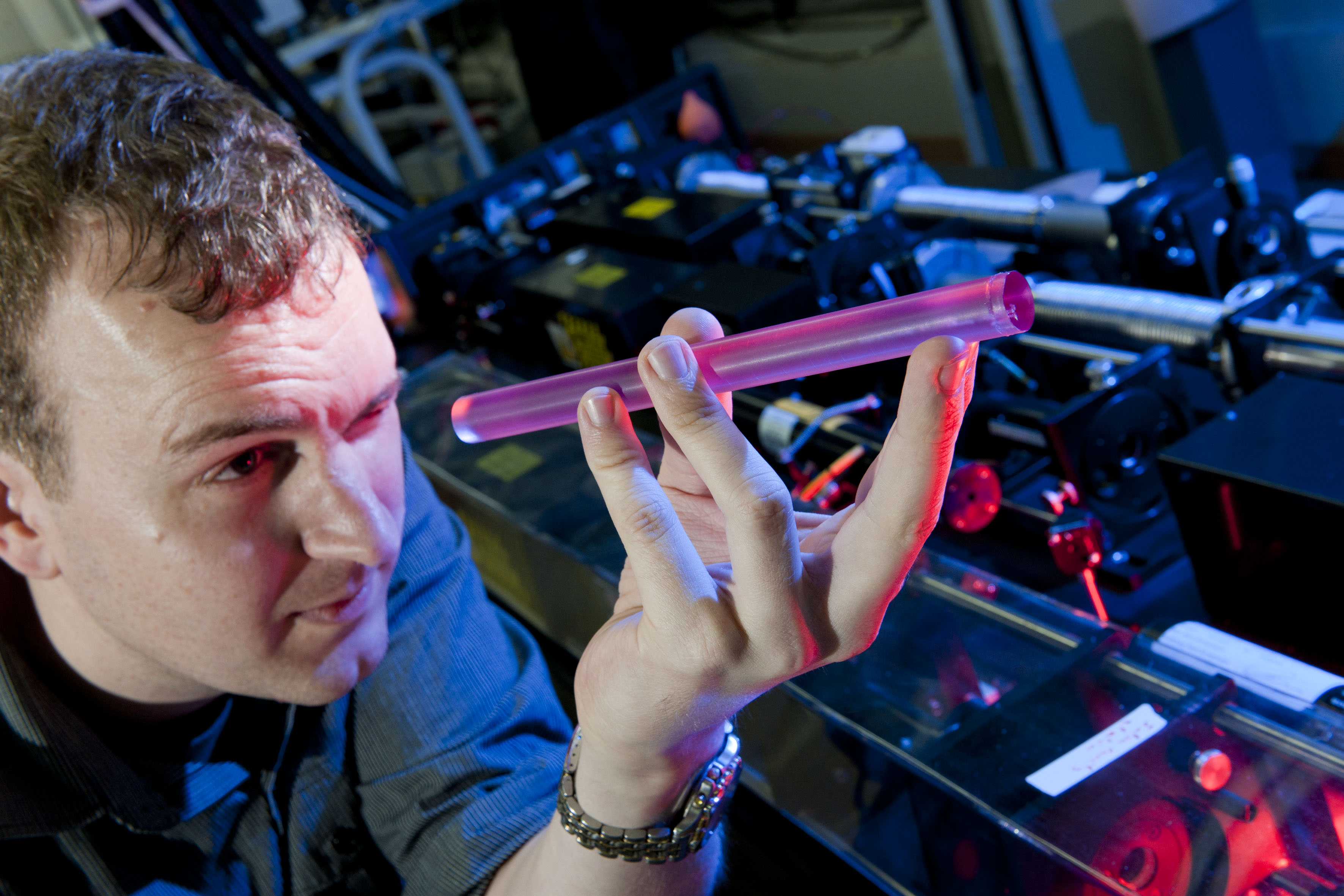

Among the technical challenges are producing laser-based systems for monitoring the condition of the plasma inside fusion reactors. The photo shows a researcher working on a laser system for the Joint European Torus

Among the technical challenges are producing laser-based systems for monitoring the condition of the plasma inside fusion reactors. The photo shows a researcher working on a laser system for the Joint European Torus

The key material used in the superconducting magnets being developed at Tokamak Energy is rare-earth barium copper oxide, a family of chemicals with special properties. Superconductors based on these compounds can sustain stronger magnetic fields than those that use other superconductor materials. The materials are delivered to Tokamak Energy as thin tapes, each containing just one micrometre (billionth of a metre) of the high-temperature superconductor within the tape.

Kingham says: “We are using tape from four of the 10 manufacturers worldwide that can make it. The quality is already good enough for our purposes, but the manufacturing volumes need to increase, and the cost needs to come down.”

For the time being, Tokamak Energy is validating its engineering using copper magnets – but in later prototypes it will need to use high-temperature superconducting magnets capable of stronger fields.

Kingham says the company’s work on superconducting magnets has gone “better than expected” and is two years ahead of schedule.

In other developments, to ensure the plasma inside Tokamak Energy’s machine is free from contaminants it must be held in a near perfect vacuum. In practice this works out at one hundred billionth of normal atmospheric pressure – the level of vacuum experienced deep in outer space.

The “superfuels” that will power a new generation of reactors

Handling tritium - an exotic gas that is highly difficult to make - is an essential part of creating energy from super-hot plasma. Pictured here is Eva Belonohy a plasma containment expert working on the international Joint European Torus

Handling tritium - an exotic gas that is highly difficult to make - is an essential part of creating energy from super-hot plasma. Pictured here is Eva Belonohy a plasma containment expert working on the international Joint European Torus

For fusion reactors to work they will need a reliable supply of an exotic gas that is unusually hard to make and which is about 2,000 times more expensive than gold.

Tritium is an isotope of hydrogen that is very rare in nature. When it is combined with deuterium – another hydrogen isotope- massive amounts of energy can be generated, as in hydrogen bombs.

Under Tokamak Energy’s plans, the first supplies of deuterium and tritium will be introduced to the company’s prototype machines in a few years’ time. Up to then, the systems will be put through their paces without any of these gases in place.

Since the amount of energy locked inside hydrogen is 10m times greater than fossil fuels, the company believes that one of its fully developed 150MW machines will run with only small amounts of fuel - about 10kg of deuterium and 15 kg of tritium a year.

If all goes to plan, Tokamak Energy's plasma vessels will eventually be filled with gases that at current market prices cost up to £100,000 a gram

If all goes to plan, Tokamak Energy's plasma vessels will eventually be filled with gases that at current market prices cost up to £100,000 a gram

To put this into perspective, a conventional power station fired by coal would require 250,000 to 400,000 tonnes of fuel to provide the equivalent amount of energy.

Deuterium is relatively abundant – about one in 6,000 of the hydrogen atoms in seawater is deuterium. Extracting it is relatively straightforward. The gas is used as an isotopic marker in research and in various processes in the chemicals sector.

Tritium on the other hand presents huge challenges. The total world inventory is thought to be no more than 40kg, much of this associated with secret military programmes.

So a fusion reactor will need to “breed” its own tritium fuel from lithium. The idea is that a neutron will hit a lithium nucleus in a “blanket” around the tokamak – and produce tritium in situ.

While deuterium is cheap, the “market price” of tritium costs is close to £100,000 a gram, making it one of the world’s most expensive materials. The price would probably fall considerably if scientists worked out how to make it in volume.

State funds provide a boost to fusion developments

Fusion reactors require a host of new technologies including remote-controlled manipulators such as this one at the Culham Centre for Fusion Energy

Fusion reactors require a host of new technologies including remote-controlled manipulators such as this one at the Culham Centre for Fusion Energy

The UK government has delivered a sizeable fillip to fusion power with the announcement of two new projects that will involve collaboration with scientists and engineers from academic research and industry.

The bigger of the projects involves a £220m design of a “commercially viable” fusion power station. The government is also setting up a £22m fusion energy research facility in Rotherham.

Both UK programmes will involve work by the UK Atomic Energy Authority’s Culham Centre for Fusion Energy in Oxfordshire together with partners such as the Nuclear Advanced Manufacturing Research Centre, part of the High Value Manufacturing Catapult – which is a Made Here Now sponsor.

The power plant - the Spherical Tokamak for Energy Production – that could be ready by 2040 or soon afterwards.

According to the UKAEA, STEP offers “the realistic prospect of constructing a powerplant by 2040”. The design of the project should be finished by 2024.

Andrea Leadsom, UK business secretary, said the STEP programme was “a bold and ambitious investment in the energy technology of the future”. She said nuclear fusion has “the potential to be an unlimited clean, safe and carbon-free energy source” adding that she wanted the first “commercially viable [fusion] machine” to be in the UK.

Governments around the world have spent heavily on developing fusion technology since the 1960s. Total expenditure on the research is put at about £2bn a year. However many of the government programmes are considered stull to be far from delivering the prospect of operational power plants. Many observers believe that fusion power based on the government projects to date is unlikely to lead to commercial systems until around the end of the century.